Increase OEE - targeted and provable

The potential for OEE gain

The Overall Equipment Effectiveness (OEE) is - isolated - a comparable abstract percentual value. For production companies OEE is a valuable for characterization of profitability and potential of improvements. Especially in press-shops, where highly efficient and cost intensive machinery for series ad large series production are dominating installations, surprising potentials of OEE gains are often accessible.

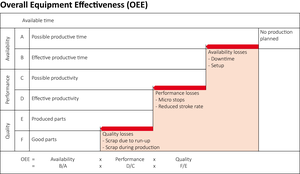

Calculation of availability, performance rate and quality

The Overall Equipment Effectiveness (OEE) is composed of the components availability, performance rate and quality. If a machine would all possible productive time in maximum velocity without and production of scrap, the OEE would be 100 %. Due to organizational and technological reasons like maintenance, setup, material changes quality tests and many more, the OEE – even of one-purpose-machines – cannot exceed a specific maximum value.

Absolute meaning of OEE and respective components

Due to specific considerations planned downtimes can be neglected from the calculation of OEE. This will raise the maximal reachable OEE value. For an absolute judgement, it is important to know the individual companies or departments calculation method. From the practical point of view, we prefer to use the three meta parameters in order to define achievable, provable targets and evaluate results. The factors describe domains, which are severally judgable and optimizable. Typical classes of losses are described in the picture.

Raise OEE with ConSenses secure and provable

ConSenses supports systematic approaches, addressing the „six big losses“, systematically.

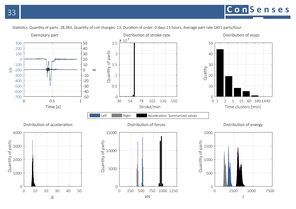

1. Reduce downtime

Auto-reports show downtimes of tools and machines neutral, precise and automatically. The special charm of this solution is, that ConSensesIoT-Systems always allow to refer to historical data in order to compare the current situations with those of a good production. Additionally, downtime information is not plotted isolated but enriched with fundamental tech data helping experts to develop first ideas of root-causes for the current task.

2. Reduce setup time

Results of setup and process behavior are comparable to former productions of the same tool or similar tools. This allows to standardize and harmonize setup processes. Here, the special charm of ConSenses solutions is, that information for workers at the machine, tool designers, maintenance staff and productions planning are derived from the same fundamental data.

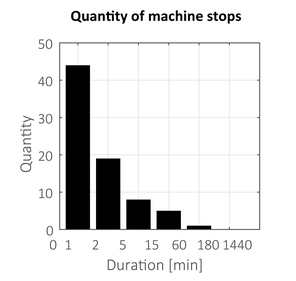

3. Reduce micro-stops

Reports show micro-stops in selectable granularity. The comparison between several processes immediately reveal those tools and processes, where micro-stops lead to higher losses than normal. The option to load and compare historical data directly, uncovers important insights and points where small actions lead to high wins. The success of measures is provable with the same tools either directly at the machine or within the automated reports that are distributed with the next checkup date.

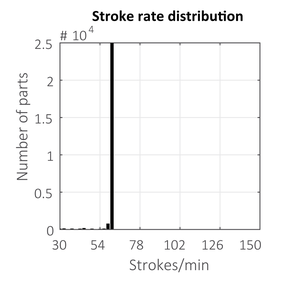

4. Raise stroke rate

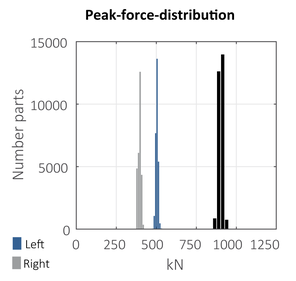

The visualization of the real stroke-rate (stroke-rate distribution right) is an easy task. Processes with a noteworthy potential for acceleration can be monitored precisely with ConSenses technology during the acceleration task. This reveals technical nonlinearities and tasks directly. We have many examples, where stroke rate could be raised safely and lasting. In the special case of machines with servo-technology, the usage of ConSenses systems opens further huge potential.

5. Reduce scrap during run-up

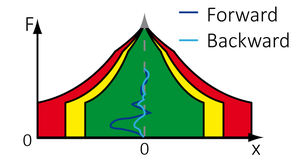

As a positive side effect of reduction of downtime, the scrap coming from ramp-up is reduced directly. Of course, databased setup-processes help to reduce losses due to ramp-up. Today it is state of technology to adjust tools by using distances. It is way more effective using the live visualization of eccentricity and nominal forces as shown in the pagoda-diagram.

6. Identify and reduce scrap during production

The OEE raise based on reduction of scrap during running production needs to be addressed in close collaboration with quality departments. The consequence of missing cooperation are monitoring systems which lead to local optimization but can result in bigger losses in the higher level. From our experience, there are always technological parameters, which lead to higher availability and product quality. Examples are:

- Presentation and correction of eccentric load and tilting of ram.

- Measurement of air in the power train.

- Cluster analysis of specific signals which are relevant in the specific process.

Practical challenges

We tackle the judgement and enhancement of process efficiency and productivity in series production every day. Beneath the handling of subjective impressions, the identification and proper handling of speaking databases is a major key for lasting success. Our systems enable us and our customers to acquire raw data with extraordinary combination of robustness, simplicity and quality, and combine this database with existing information patterns. During the usage of data, we consequently inquire the origin of the data and the expectable and measurable quality of the content.

This simple approach often leads to surprising insights and impressive changes.

And now?

The good message is: At the very end, good solutions are always easy to understand. Experience and knowledge allow us to identify the important points from many facets fast and targeted, without leaving other aspect out of sight. We help making the right steps. Your first step could be, to make schedule a call here. We bring along the needed experience to make things easy. We help making the right steps. Your first step could be, to make schedule a call here. We bring along the needed experience to make things easy.